Guide to Silicone Sealants for Different Applications

Choosing the right silicone sealant is essential for ensuring durability and long-lasting performance in various projects. From general-purpose sealing to specialized applications, each type of silicone sealant has unique properties tailored for specific uses. This guide will help you understand which sealant best suits your needs, focusing on the three silicone sealants offered by AutoStar and OPTIMUS.

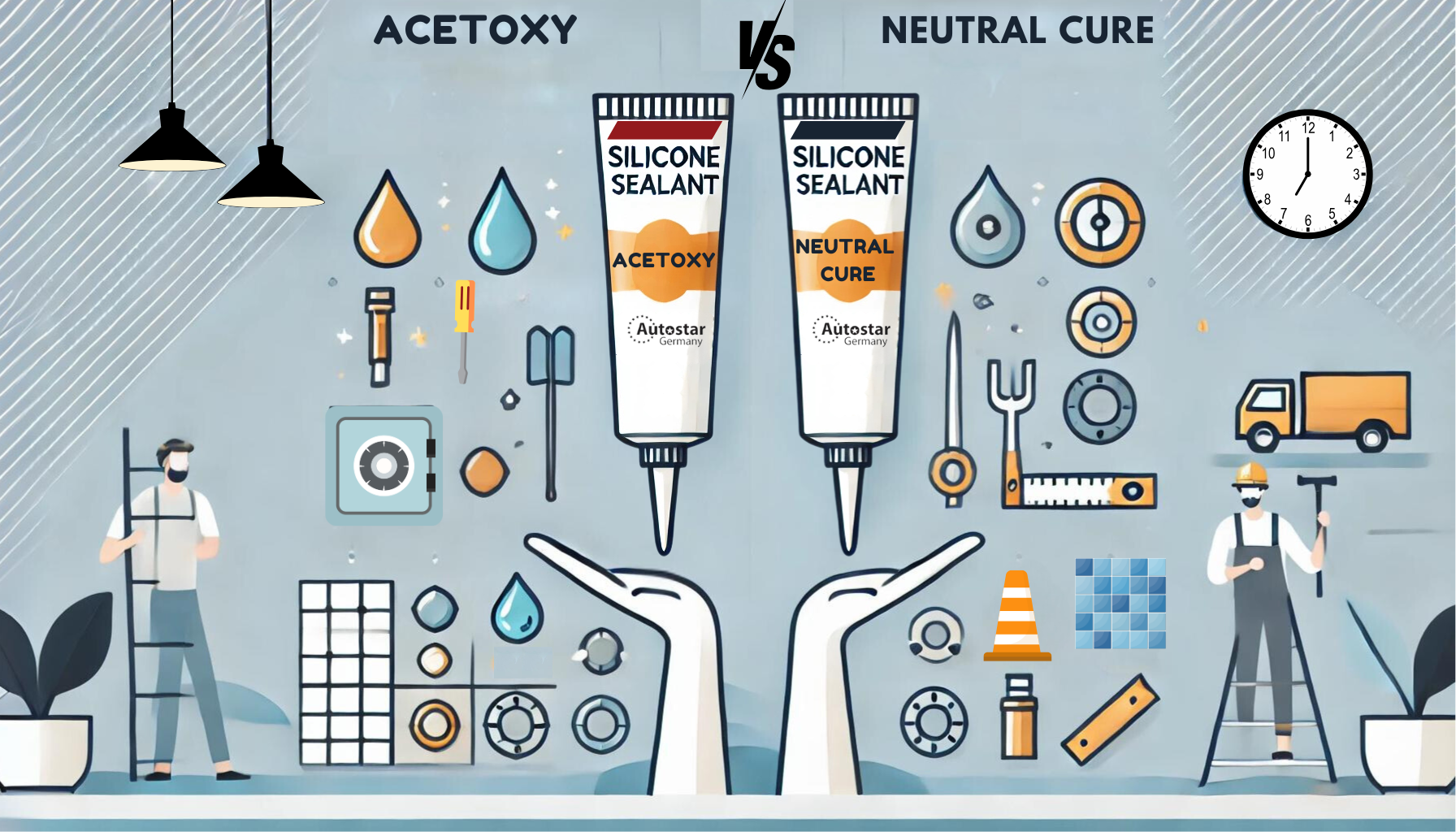

For a comparison of acetoxy and neutral cure silicone options, see our blog: Acetoxy vs. Neutral Cure Silicone Sealants: Key Differences for DIY & Professional Projects.

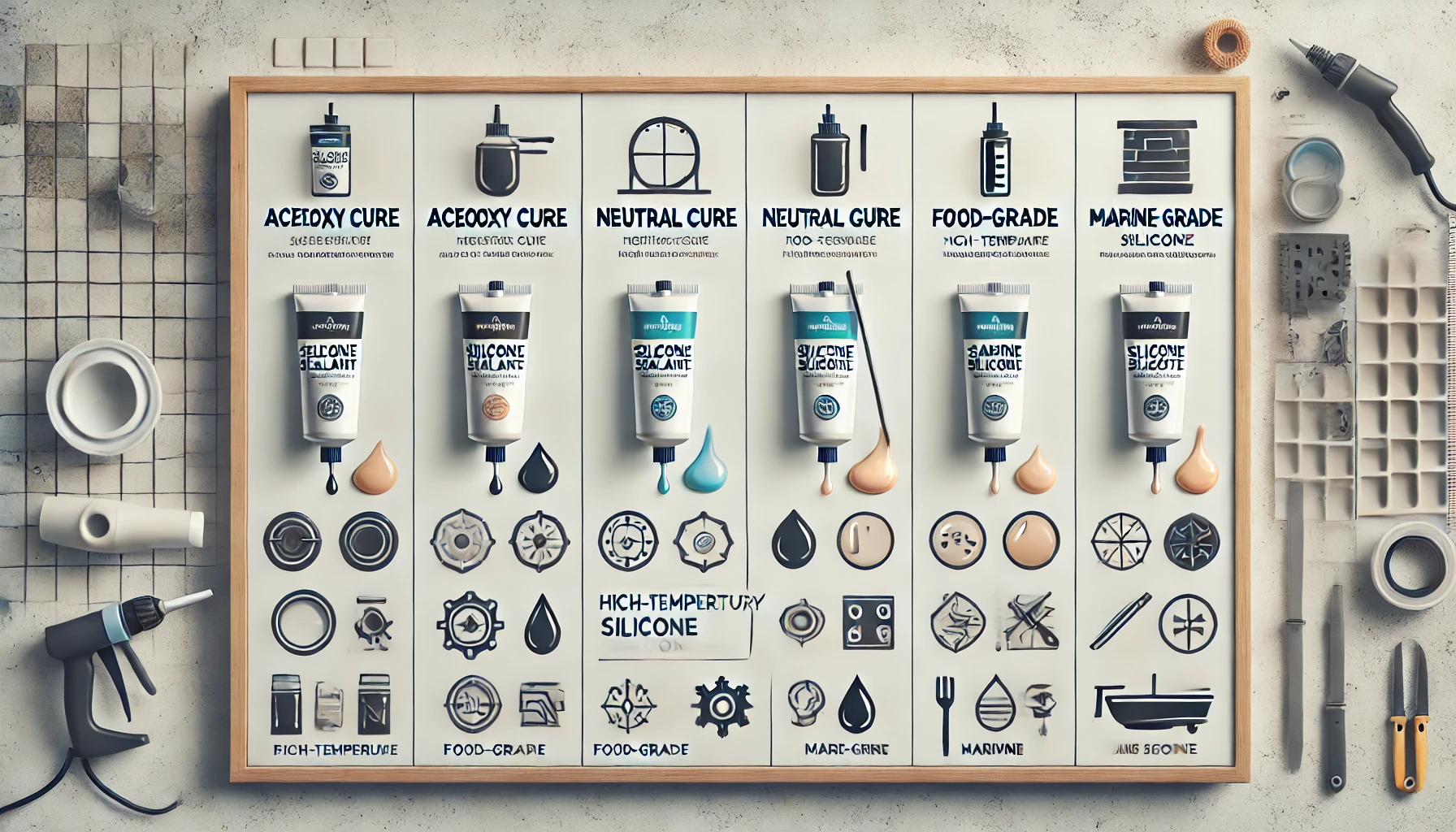

Quick Reference Table: Types of Silicone Sealants

Sealant Type | Best For | Common Applications | Product Recommendation |

Multi-Purpose Silicone | Indoor and outdoor general use | Sinks, windows, DIY repairs | |

Windscreen & Glass Bonding | Automotive and glass bonding | Car windshields, glass installations | |

Waterproof Acetoxy Silicone | High-moisture areas | Bathrooms, kitchens, wet areas |

Understanding Silicone Sealants and Their Benefits

Silicone sealants offer several advantages over other types of sealants, such as acrylic or polyurethane. Key benefits include:

- Flexibility: Silicone remains flexible after curing, making it ideal for joints that may experience movement or vibration.

- Water and Weather Resistance: Highly resistant to moisture, UV rays, and extreme temperatures, silicone is suitable for both indoor and outdoor applications.

- Longevity: Silicone maintains strong adhesion and elasticity over time, reducing the need for frequent reapplications.

This makes silicone an ideal choice for applications where a durable, waterproof, and flexible seal is required. For an in-depth guide, read our Complete Guide to Choosing Silicone Sealants.

1. Multi-Purpose Silicone Sealant

A versatile choice for a wide range of applications, multi-purpose silicone sealants provide a flexible, durable, and waterproof bond suitable for general sealing tasks. These sealants are ideal for both indoor and outdoor use, offering excellent adhesion to common surfaces like glass, metal, wood, and ceramics.

Product Recommendation:

AutoStar Germany Multi-Purpose Silicone Sealant – Available in White, Black, Gray, and Clear (310ml)

Best Uses:

- Indoor Sealing: Around sinks, countertops, and backsplashes.

- Outdoor Applications: Windows, doors, and other fixtures exposed to the elements.

- DIY Repairs: Household repairs and general sealing tasks.

Advantages:

- Fast curing and easy application.

- Available in multiple colors (white, black, gray, clear) to match different surfaces.

- Suitable for a variety of materials and environments.

2. Windscreen and Glass Bonding Sealant

For automotive and glass bonding applications, a specialized sealant is essential to withstand temperature variations, vibrations, and environmental exposure. Windscreen and glass bonding silicone sealants are specifically formulated to create a strong, flexible bond ideal for car windshields and glass surfaces.

Product Recommendation:

AutoStar Germany Windscreen Glass Sealant Silicone Bonding Adhesive Glue (310ml)

Best Uses:

- Automotive Applications: Ideal for bonding and sealing car windshields and side windows.

- Glass Bonding: Provides a strong bond for glass installations requiring flexibility.

Advantages:

- Withstands vibrations and temperature changes, making it perfect for automotive applications.

- Durable and flexible for long-lasting bonds.

Application Tip: Ensure surfaces are clean and dry before application to achieve optimal adhesion.

3. Waterproof Acetoxy Silicone Sealant

For areas exposed to high moisture, such as bathrooms and kitchens, waterproof acetoxy silicone sealants provide a reliable, waterproof seal that prevents mold and mildew growth. Acetoxy silicone is known for its fast curing time and strong adhesion to non-porous surfaces, making it a popular choice for wet areas.

Product Recommendation:

Best Uses:

- Bathroom Sealing: Around sinks, bathtubs, and shower enclosures.

- Kitchen Applications: Sealing around kitchen sinks, countertops, and backsplashes.

- Moisture-Prone Areas: Provides a durable waterproof barrier that resists mold and mildew.

For a comparison between acetoxy and neutral cure silicone, see our blog on Acetoxy vs. Neutral Cure Silicone Sealants: Key Differences for DIY & Professional Projects.

Factors to Consider When Choosing a Silicone Sealant

To select the best silicone sealant, consider the following factors based on your project’s requirements:

1. Application Environment

- For shower stalls or sinks, a waterproof acetoxy silicone sealant like OPTIMUS is ideal, while AutoStar Windscreen Glass Sealant is best for outdoor glass exposed to temperature changes.

2. Material Compatibility

- Multi-purpose silicone works well on wood and plastic surfaces, while AutoStar Glass Sealant is specifically designed for automotive glass applications.

3. Color Options

- Choose a color that best matches your project. AutoStar Germany Multi-Purpose Silicone Sealant is available in white, black, gray, and clear, while OPTIMUS Waterproof Silicone comes in white, clear, and black for versatile options.

4. Curing Time

- Fast-curing acetoxy silicone may be more convenient for quick fixes, while other types may require longer curing times for stronger, more flexible bonds.

Application Tips for Best Results

To achieve a strong, durable seal with silicone, follow these best practices:

- Prepare the Surface: Ensure the surface is clean, dry, and free from dust or oils.

- Apply Evenly: Use steady, even pressure to apply the sealant, ensuring the joint is filled.

- Tool the Sealant: Smooth the sealant with a caulking tool for a professional finish.

- Allow for Curing Time: Avoid disturbing the sealant until it has fully cured to achieve the strongest bond.

For more guidance on choosing silicone sealants, read our Complete Guide to Choosing Silicone Sealants.

Troubleshooting Tips for Silicone Sealant Applications

Problem 1: Silicone Sealant Not Curing Properly

- Solution: Ensure the temperature is within the recommended range (5°C to 35°C) and check the expiration date of the sealant.

Problem 2: Poor Adhesion

- Solution: Clean the surface thoroughly and ensure it is dry before application. Some materials may require a primer for optimal adhesion.

Problem 3: Discoloration or Mildew Growth

- Solution: Use a mold-resistant, waterproof acetoxy silicone for high-moisture areas, like the OPTIMUS Waterproof Silicone Sealant.

Problem 4: Removing Old Silicone Before Reapplying

- Solution: Use a silicone remover or a utility knife to carefully scrape away old sealant. Clean the area thoroughly before applying new silicone for the best adhesion.

Frequently Asked Questions (FAQ)

Q1: How long does it take for silicone sealant to cure?

Most silicone sealants cure within 24-48 hours. Acetoxy silicone, like the OPTIMUS Waterproof Silicone, generally cures faster than neutral cure silicone.

Q2: Can I use multi-purpose silicone in the bathroom?

Yes, multi-purpose silicone can be used in the bathroom; however, for areas exposed to constant moisture, a waterproof acetoxy silicone is more effective in preventing mold and mildew.

Q3: Is it safe to use glass bonding sealant for non-automotive applications?

Yes, the AutoStar Windscreen Glass Sealant can be used for other glass bonding applications, but it’s specifically designed to withstand the unique conditions of automotive environments.

Q4: How can I remove old silicone sealant before reapplying?

To remove old silicone, use a silicone remover or carefully scrape it away with a utility knife. Clean the surface thoroughly before applying new silicone for the best adhesion.

Conclusion: Choose the Right Silicone Sealant for Every Application

Whether you’re sealing household fixtures, tackling automotive repairs, or working in high-moisture environments, selecting the correct silicone sealant is essential for achieving long-lasting durability and optimal performance. From the versatile AutoStar Germany Multi-Purpose Silicone to the specialized OPTIMUS Waterproof Acetoxy and AutoStar Windscreen Glass Sealants, our collection has a solution for every project need.

Ready to achieve professional-quality results? Explore our complete Silicone Sealant Collection to find durable, waterproof solutions for your next project!