10 Essential Uses of Silicone Sealants in Everyday Life

Silicone sealants are among the most versatile tools available for both professional and DIY projects. Whether you’re repairing a leaky window, assembling furniture, or protecting delicate electronics, silicone sealants are the unsung heroes of home and industrial applications. Their flexibility, water resistance, and durability make them indispensable for a variety of tasks.

In this article, we’ll explore 10 essential uses of silicone sealants, providing you with practical insights and tips to make the most of this amazing product.

What Are Silicone Sealants?

Silicone sealants are flexible, rubber-like substances used to seal gaps, bond surfaces, and protect materials from water, air, and other external factors. Made from silicone polymers, these sealants are highly resistant to extreme temperatures, UV rays, and moisture, making them ideal for long-lasting applications indoors and outdoors.

Sealing Leaky Windows and Doors

One of the most common uses of silicone sealants is fixing leaky windows and doors. Drafty windows can increase energy bills, while leaks can lead to water damage over time. Silicone sealants provide a weatherproof, airtight seal to keep moisture and drafts at bay.

Simply clean the area, apply the sealant along the edges, and smooth it out for a professional finish. This quick fix can save money on energy costs and protect your home from unwanted water damage.

Waterproofing Bathrooms and Kitchens

Bathrooms and kitchens are prone to water exposure, which can cause mold and mildew growth. Silicone sealants are perfect for sealing gaps around sinks, bathtubs, shower enclosures, and tiles.

Their waterproof properties ensure that water doesn’t seep into unwanted areas. For example, you can use clear silicone sealants around your kitchen countertop edges or bathroom tiles for a clean and long-lasting seal.

Automotive Repairs

Did you know that silicone sealants play a crucial role in vehicle maintenance? From sealing windshields to minor engine repairs, silicone sealants can withstand the high temperatures and vibrations found in cars.

For instance, they can be used to seal leaks in a car’s cooling system or to create strong bonds in parts that require flexibility. Their versatility makes them a go-to for mechanics and car enthusiasts alike.

Electronics Protection

Silicone sealants are widely used in the electronics industry to protect sensitive components. They shield circuit boards, connectors, and other electronic parts from moisture, dust, and environmental damage.

By applying a thin layer of silicone sealant, you can extend the lifespan of your gadgets and ensure they remain functional even in humid conditions.

DIY Craft Projects

If you’re into DIY crafts, silicone sealants can unlock endless creative possibilities. They can be used to make molds for candles or jewelry, glue materials together, or create decorative designs on various surfaces.

Their flexibility and quick curing time make them ideal for projects that require precision and durability. You can even experiment with colored silicone sealants to add a unique touch to your crafts.

Industrial Applications

Silicone sealants are indispensable in industries like construction, aerospace, and marine due to their heat resistance and durability. They are used to seal joints, bond materials, and protect structures from environmental damage.

For example, in construction, silicone sealants are applied to glass panels in skyscrapers to create weatherproof seals that withstand high winds and temperature changes.

Roof and Gutter Repairs

Cracks and leaks in roofs or gutters can lead to costly water damage. Silicone sealants provide a reliable solution for sealing gaps and preventing water penetration.

Simply apply the sealant to the damaged area, and it will create a waterproof barrier that can withstand harsh weather conditions.

Aquariums and Fish Tanks

Silicone sealants are non-toxic and waterproof, making them ideal for aquariums and fish tanks. They can be used to bond glass panels or repair leaks without harming aquatic life.

Their durability ensures that the aquarium remains leak-free for years, giving you peace of mind while caring for your fish and plants.

Furniture Assembly and Repairs

Silicone sealants are great for repairing and assembling furniture. They can bond materials like wood, glass, or metal, providing a secure and flexible hold.

For example, if your glass tabletop has come loose from its frame, silicone sealants can reattach it seamlessly and invisibly.

HVAC Systems

HVAC systems require proper sealing to ensure energy efficiency and prevent air leaks. Silicone sealants are used to seal ducts, insulate joints, and improve the overall performance of HVAC systems.

By reducing air leaks, silicone sealants help lower energy costs and maintain consistent indoor temperatures.

How to Choose the Right Silicone Sealant

Choosing the right silicone sealant depends on the type of project. Here are some factors to consider:

- Type of Surface: Ensure the sealant is compatible with the materials you’re working with, such as glass, metal, or plastic.

- Curing Time: Some projects may require faster curing sealants.

- Application Environment: Opt for heat-resistant or waterproof sealants depending on where the product will be used.

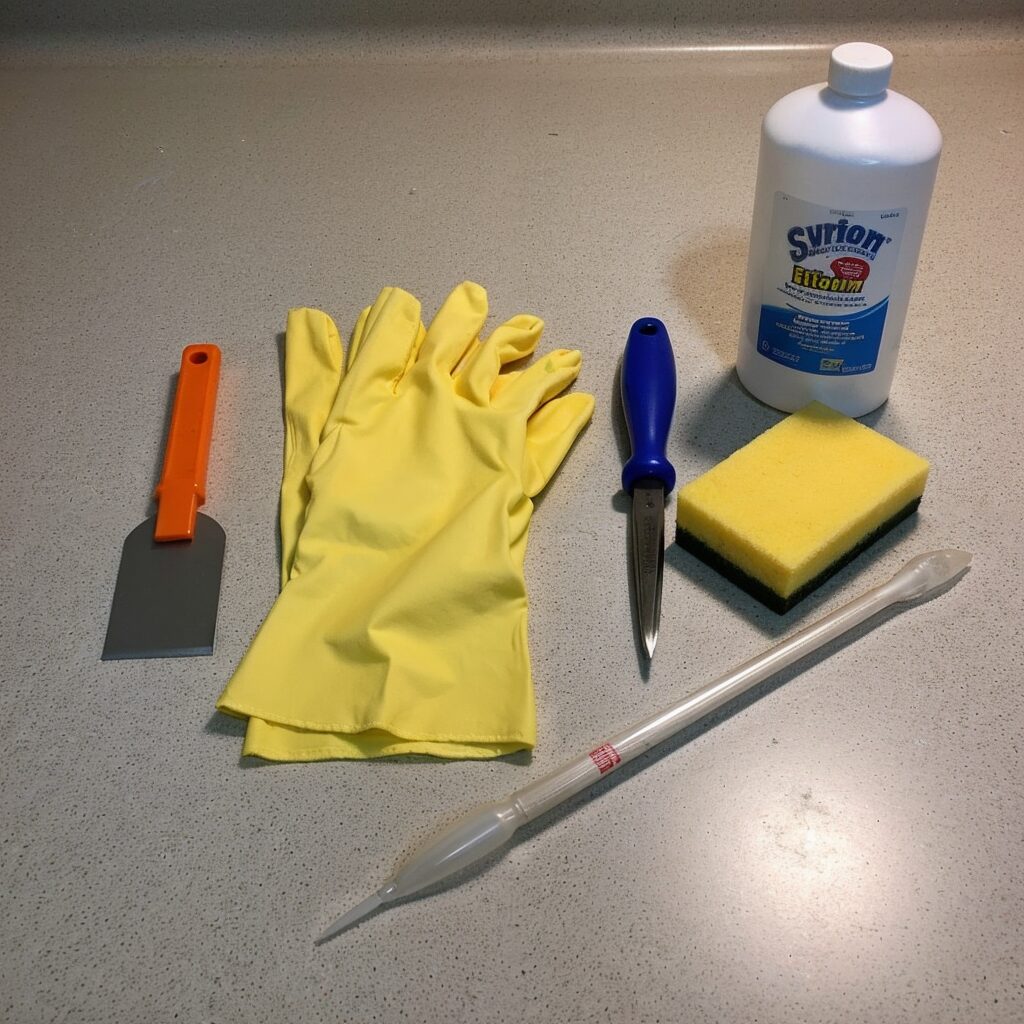

Tips for Using Silicone Sealants Effectively

- Prepare the Surface: Ensure the surface is clean, dry, and free of dust or grease.

- Use a Caulking Gun: For an even application, use a caulking gun to apply the sealant.

- Smooth the Sealant: Use a wet finger or a caulking tool to smooth the sealant for a clean finish.

- Follow Instructions: Always check the product label for curing times and application tips.

Conclusion

Silicone sealants are incredibly versatile and offer solutions for everything from home repairs to industrial applications. Their flexibility, durability, and waterproof properties make them a must-have for professionals and DIY enthusiasts alike.

Whether you’re sealing a leaky window, repairing a roof, or protecting your electronics, silicone sealants can simplify your life and save you time and money.

FAQs

What makes silicone sealants different from other sealants?

Silicone sealants are highly flexible, waterproof, and resistant to extreme temperatures, making them more durable than other types of sealants.

Can I use silicone sealants for outdoor applications?

Yes, silicone sealants are UV-resistant and weatherproof, making them perfect for outdoor projects.

Are silicone sealants safe for aquariums?

Yes, non-toxic silicone sealants are safe for aquariums and aquatic life.

How long does silicone sealant take to cure?

Curing time varies but generally takes 24–48 hours for a full cure.

Can silicone sealants be painted over?

Most silicone sealants are not paintable. However, some hybrid sealants allow for painting.

Are silicone sealants eco-friendly?

While silicone sealants are durable, eco-friendly options are available with low VOC levels.