Selecting the right silicone sealant can make a significant difference in the durability and quality of a project. From sealing bathroom fixtures to tackling outdoor construction, each type of sealant offers unique properties suited to specific applications. This guide explores the main types of silicone sealants, their key characteristics, and essential tips to help you choose the best one for your needs.

Understanding Silicone Sealants

Silicone sealants are flexible, waterproof compounds that create a durable, weather-resistant seal. They’re widely used in both DIY and professional projects because of their versatility and ability to adhere to various surfaces, including glass, metal, wood, and ceramic. However, not all silicone sealants are the same—each type has unique characteristics that make it suitable for specific environments and materials.

For a deep dive into choosing silicone sealants between popular options like acetoxy and neutral cure, read our Choosing the Right Silicone Sealant: Acetoxy vs. Neutral Cure blog.

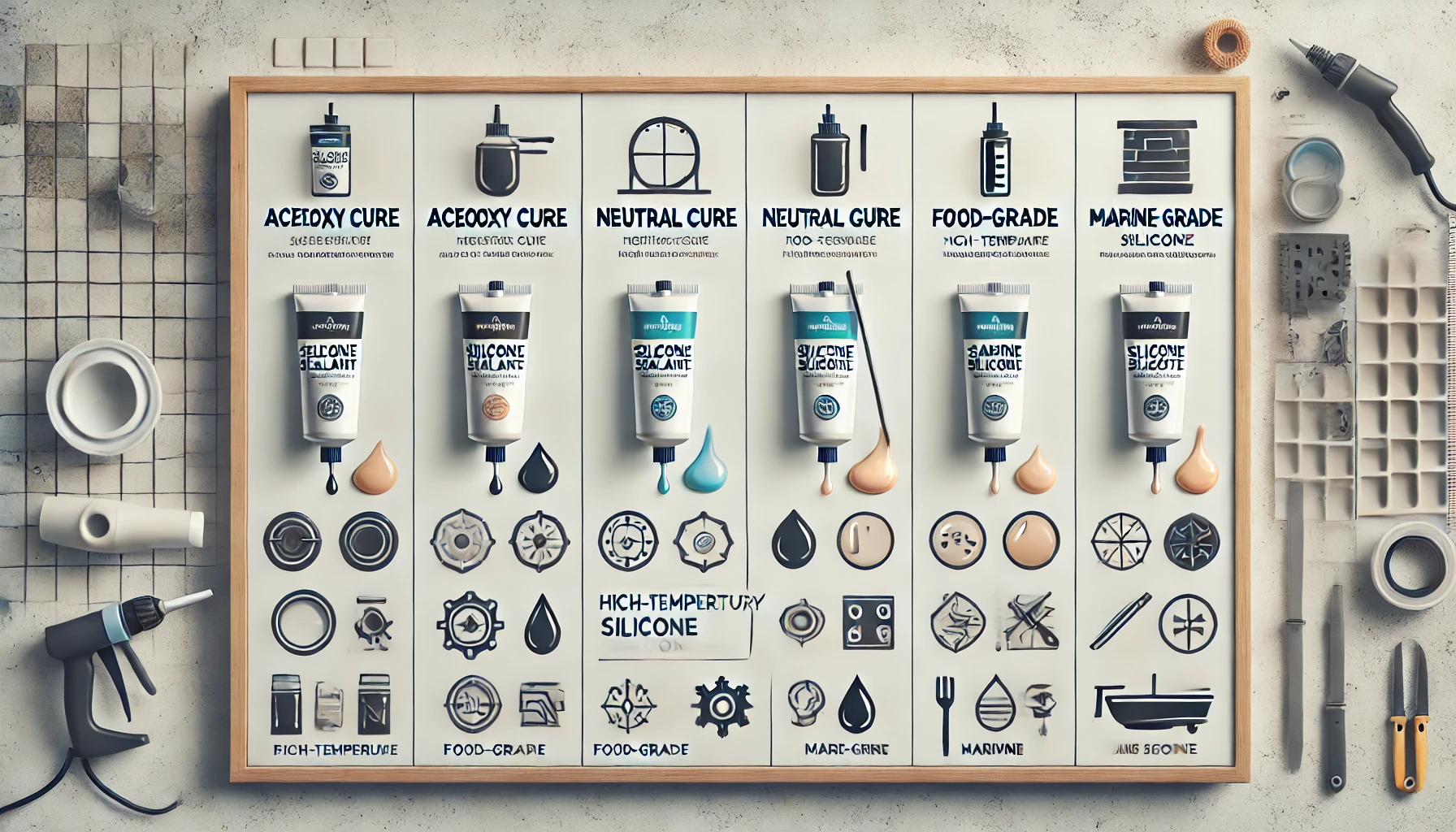

Types of Silicone Sealants

Below is a breakdown of the most common types of silicone sealants, each designed to meet particular needs. Refer to the comparison table for a quick overview of each type’s ideal applications.

| Sealant Type | Typical Curing Time | Ideal For | Suitable Materials | Common Uses |

| Acetoxy Cure | Fast | Non-porous surfaces | Glass, metal, tiles | e.g., shower doors, bathroom tiles |

| Neutral Cure | Moderate | Sensitive materials | Metals, wood, concrete | e.g., window frames, door frames |

| High-Temperature | Moderate | High-heat environments | Metal, glass | e.g., engine parts, fireplaces |

| Food-Grade | Moderate | Food-safe applications | Countertops, sinks, appliances | e.g., kitchen countertops, food prep areas |

| Marine | Slow | Constant water exposure | Various (waterproof requirement) | e.g., boats, water tanks |

1. Acetoxy Cure Silicone Sealant

Acetoxy cure silicone, also known as “acid cure,” releases acetic acid as it cures, which gives it a vinegar-like odor. Known for its quick drying time and strong adhesion to non-porous surfaces, acetoxy cure silicone is often used in general-purpose applications.

- Ideal For: Non-porous surfaces like glass, metal, and ceramic tiles.

- Common Uses: Bathrooms, kitchens, and glazing applications.

- Advantages: Fast curing time, strong bond, affordable.

- Limitations: Can corrode metals like aluminum, has a strong odor during curing.

Example Use: Acetoxy silicone is ideal for sealing glass shower doors and bathroom tiles where a fast-drying, waterproof seal is needed.

For more information, visit our Acetoxy Silicone Product Page.

2. Neutral Cure Silicone Sealant

Neutral cure silicone releases alcohol or a neutral substance as it cures, making it safe to use on a broader range of materials, including metals and porous surfaces. Neutral cure is highly flexible and durable, making it ideal for high-movement joints.

- Ideal For: Sensitive materials like metals, wood, and concrete.

- Common Uses: Window frames, door frames, and automotive applications.

- Advantages: Non-corrosive, low odor, suitable for porous and non-porous materials.

- Limitations: Generally slower curing time, higher cost.

Example Use: Neutral cure silicone is perfect for sealing metal window frames, especially in areas that experience temperature changes.

For a detailed guide, check out our Neutral Cure Silicone Product Page.

3. High-Temperature Silicone Sealant 🔥

High-temperature silicone sealant is formulated to withstand extreme temperatures, making it ideal for applications exposed to heat, such as engines, exhaust systems, and fireplaces. This type of silicone offers exceptional durability under high heat.

- Ideal For: Environments exposed to high heat.

- Common Uses: Automotive engines, exhaust pipes, and fireplaces.

- Advantages: Heat-resistant, durable, flexible.

- Limitations: Typically not suitable for underwater or submersion applications.

Example Use: Ideal for sealing around an oven door or engine component to ensure a heat-resistant seal.

4. Food-Grade Silicone Sealant 🍽️

Food-grade silicone is designed to be safe for areas where it might come into contact with food or drink. These sealants are FDA-approved and commonly used in kitchens and food processing facilities.

- Ideal For: Applications where food safety is a priority.

- Common Uses: Kitchen countertops, sinks, and food processing equipment.

- Advantages: Non-toxic, safe for incidental food contact, durable.

- Limitations: Typically more expensive due to food-safe formulation.

Example Use: Great for sealing around a kitchen sink where it may come into indirect contact with food.

5. Marine Silicone Sealant 🌊

Marine silicone sealant is waterproof and UV-resistant, designed for use on boats and other marine equipment. This type offers excellent adhesion in wet environments, making it suitable for submerged or exposed water applications.

- Ideal For: Environments with continuous exposure to water.

- Common Uses: Boats, water tanks, and marine equipment.

- Advantages: Waterproof, UV-resistant, durable in wet conditions.

- Limitations: Not typically heat-resistant, may not bond well to some plastics.

Example Use: Perfect for sealing boat fixtures or water tanks where a long-lasting, waterproof bond is essential.

Factors to Consider When Choosing a Silicone Sealant

When selecting a silicone sealant, keep the following factors in mind to ensure optimal performance and durability:

1. Material Compatibility

- Some sealants, like acetoxy cure, are suitable only for non-porous surfaces like glass or tiles, while neutral cure silicone can be used on metals, wood, and concrete.

2. Application Environment

- Consider the environment where the sealant will be used. For example, high-temperature silicone is ideal for heat exposure, while marine silicone is essential for waterproof applications.

3. Curing Time

- If you need a fast bond, acetoxy silicone cures quickly. However, if flexibility and durability are priorities, neutral cure silicone’s slower curing time is worth the wait.

4. Odor Sensitivity

- For indoor applications, a low-odor sealant like neutral cure silicone is ideal, as it won’t release the strong smell associated with acetoxy types.

5. Environmental Resistance

- If the sealant needs to withstand specific environmental conditions, like UV exposure or extreme heat, choose one formulated for those requirements. Marine silicone and high-temperature silicone are best for outdoor or heat-exposed projects.

For more in-depth considerations, see our Guide to Silicone Sealants for Different Applications.

Application Tips for Silicone Sealants

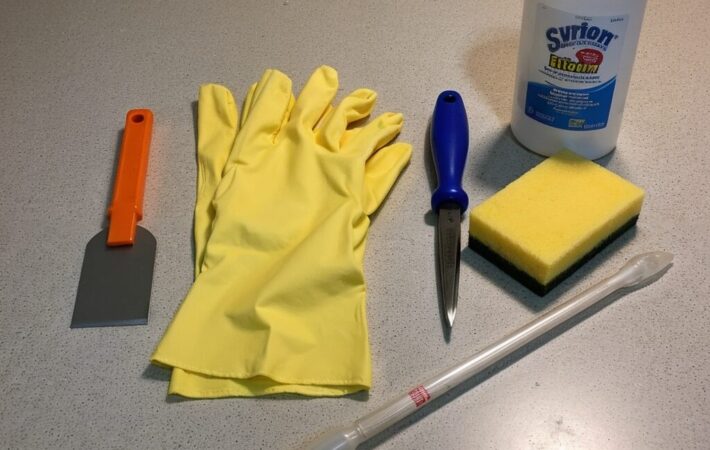

Achieving a smooth, durable seal with silicone requires some preparation and technique. Here are some helpful tips:

- Clean the Surface: Make sure the surface is clean, dry, and free from dust or oils, as these can impact adhesion.

- Use Painter’s Tape: Applying tape along both sides of the joint helps create a clean, professional finish.

- Apply Even Pressure: Use a steady, even pressure to apply the sealant, ensuring it fills the joint completely.

- Tool the Sealant: Use a caulking tool or your finger (dipped in soapy water) to smooth the sealant and remove any excess.

- Allow Proper Curing Time: Avoid exposing the sealant to moisture or heavy movement until it’s fully cured.

Troubleshooting Tips for Silicone Sealants

Problem 1: Silicone Not Curing Properly

- Solution: Ensure the area has the right temperature and humidity, typically between 5°C and 35°C. Double-check the expiration date, as older silicone may not cure effectively.

Problem 2: Poor Adhesion

- Solution: Ensure the surface is clean, dry, and suitable for the specific sealant type. For porous surfaces, choose a neutral cure sealant.

Problem 3: Discoloration Over Time

- Solution: Use UV-resistant silicone for outdoor applications to prevent color fading and degradation from sun exposure.

Problem 4: Removing Old Silicone Sealant

- Solution: Use a silicone remover or a utility knife to scrape away the old sealant. Clean the surface thoroughly before applying new silicone for the best adhesion.

Frequently Asked Questions (FAQ)

Q1: Can I paint over silicone sealant?

Most silicone sealants are not paintable. For paintable options, consider using an acrylic or hybrid sealant.

Q2: How long does it take for silicone to cure?

Curing times vary by type, but acetoxy silicone typically cures in 24 hours, while neutral cure may take up to 48 hours. High-temperature and marine sealants may also require a full 24–48 hours to reach complete curing.

Q3: Is there a difference between waterproof and water-resistant silicone?

Yes, waterproof silicone can withstand continuous exposure to water, making it ideal for submerged or marine applications. Water-resistant silicone, on the other hand, is best suited for occasional or indirect water contact, such as bathroom fixtures.

Q4: Can silicone sealants be used outdoors?

Absolutely. Many silicone sealants, such as marine and neutral cure, are UV-resistant and designed to withstand outdoor conditions, making them excellent choices for exterior applications.

Conclusion: Choosing the Right Silicone Sealant for Your Project

Whether sealing a bathroom fixture, safeguarding a kitchen countertop, or working on a high-heat project, selecting the right silicone sealant is essential for achieving durable, effective results. From quick-drying acetoxy silicone for non-porous surfaces to flexible, corrosion-resistant neutral cure silicone for sensitive materials, we offer a silicone sealant for every project.

Ready to find the ideal sealant for your needs? Explore our complete Silicone Sealant Collection to ensure durability, waterproofing, and long-lasting results for every application!

Leave a comment

Your email address will not be published. Required fields are marked *